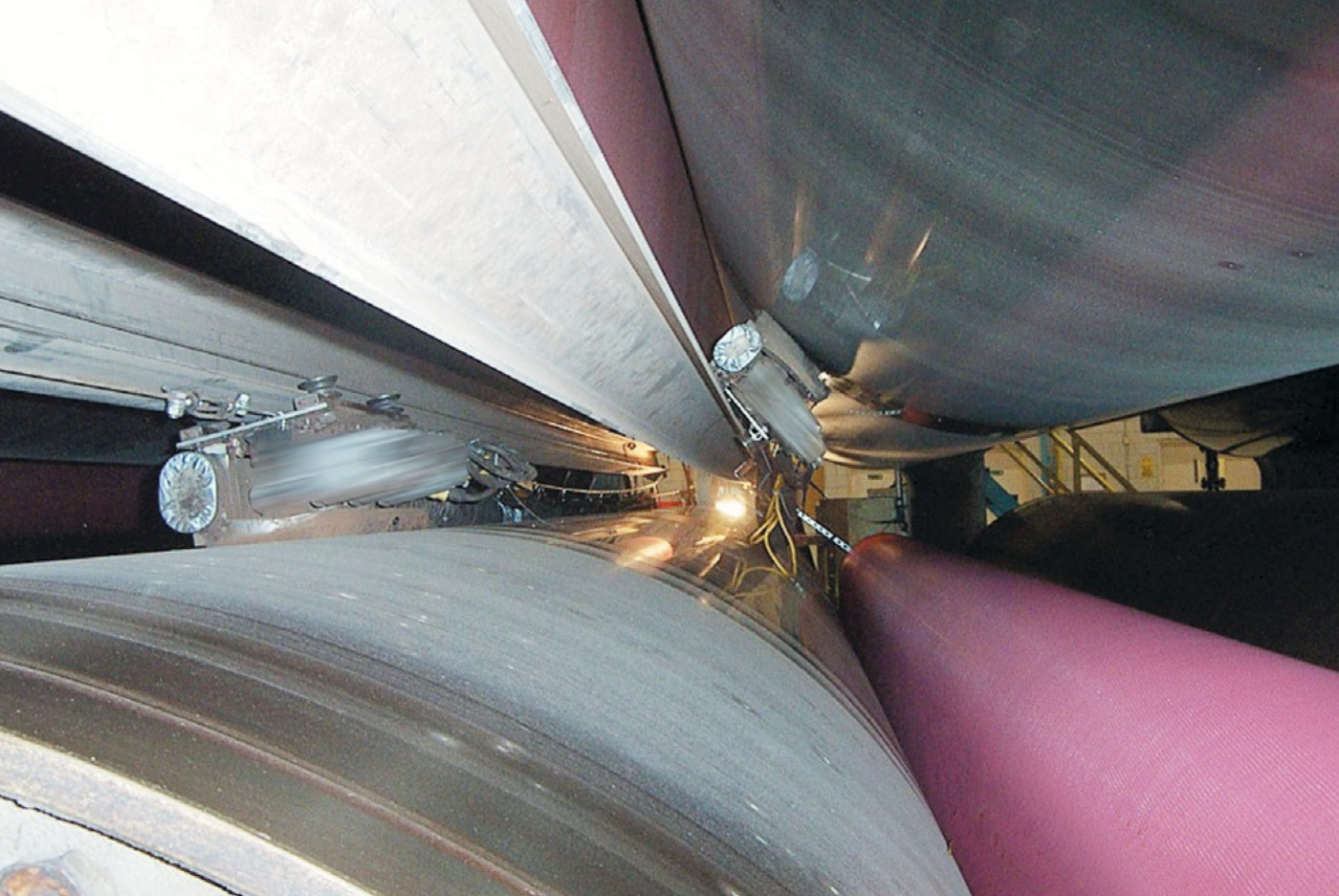

World’s Fastest Industrial Dryer Can Cylinder Cleaning Service

Reduce steam consumption and improve efficiency with fewer page breaks and less unplanned downtime.

Maximize your shut down time with the world’s fastest industrial cleaning system. Clean-up to 12 cans in 12 hours with our expert technicians and cutting edge process.

Cleaning Targets: Starch, coating and pitch build up as well as rust, hot melts and contaminants from recycled pulp.

Several mills have experienced over 10% improvement in production after having dryer can cylinders cleaned!

Before