Unveiling the game-changing nonstick properties of heat shrinkable fluoropolymers and their incredible impact on cost savings and efficiency in the pulp and paper sector

Introduction

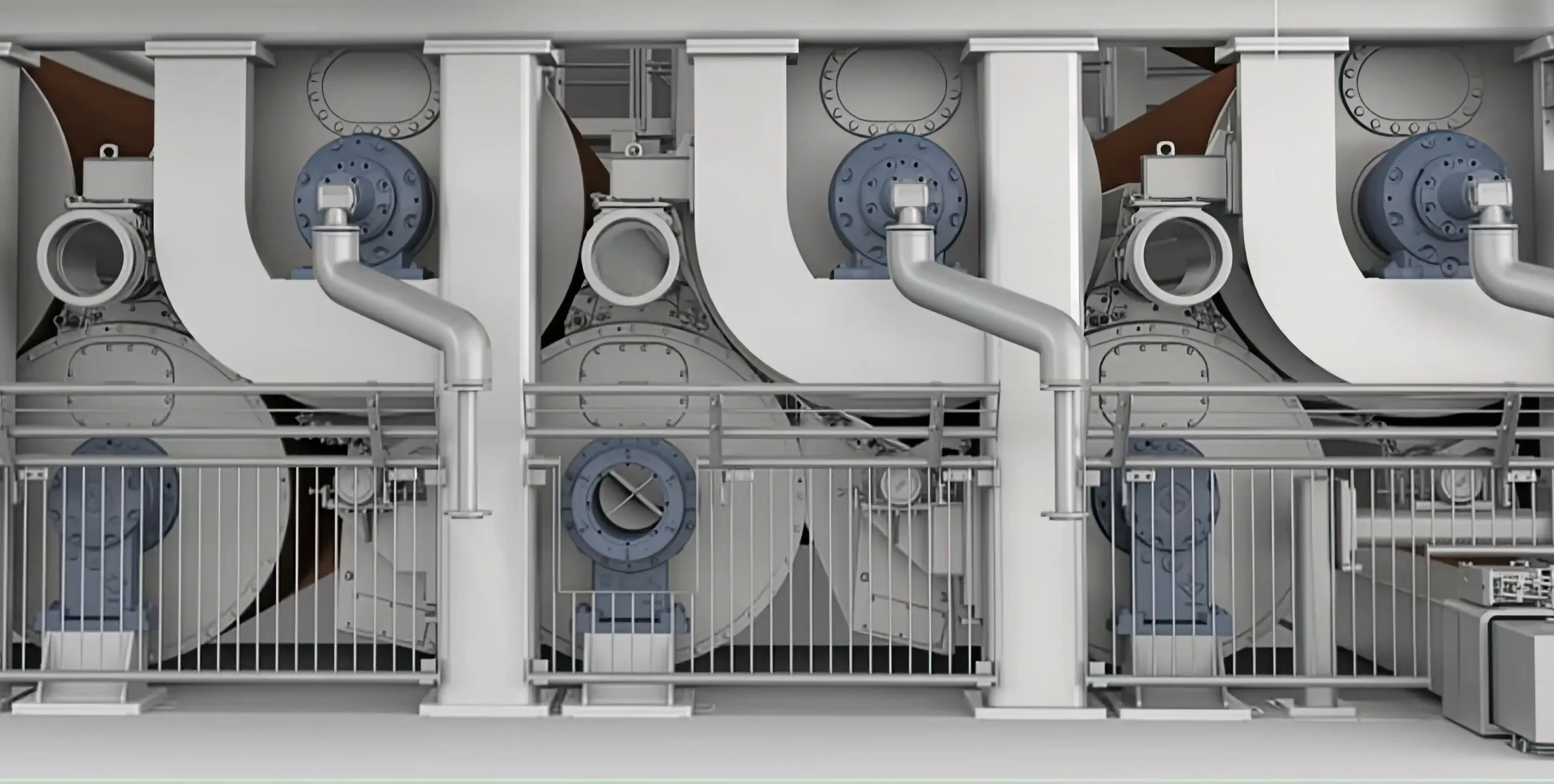

In the ever-evolving world of the pulp and paper industry, the search for innovative materials that enhance production efficiency and product quality is constant. Among the plethora of advanced materials, heat shrinkable fluoropolymers, specifically PTFE, PFA, and FEP, have emerged as the superheroes of nonstick technology for roller applications. In this article, we dive deep into the world of these nonstick champions, exploring their unique properties, and uncovering their groundbreaking role in revolutionizing the pulp and paper industry by reducing sticking issues and cutting costs.

Section 1: The Nonstick Superheroes – PTFE, PFA, and FEP Heat Shrinkable Fluoropolymers

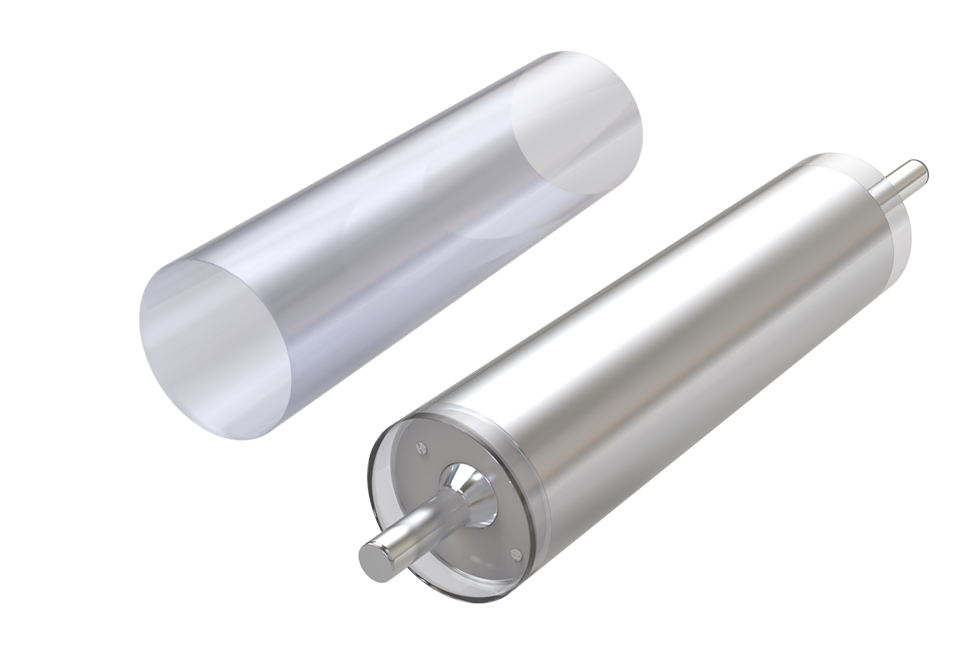

PTFE (Polytetrafluoroethylene), PFA (Perfluoroalkoxy), and FEP (Fluorinated Ethylene Propylene) are high-performance heat shrinkable fluoropolymers that boast unparalleled nonstick properties. Known for their exceptional chemical and thermal resistance, as well as their low coefficient of friction, these materials are virtually impervious to adhesion, making them the ideal choice for pulp and paper industry roller applications.

Section 2: Eliminating Sticking and Buildup on Rollers

The nonstick properties of PTFE, PFA, and FEP heat shrinkable fluoropolymers have a profound impact on the pulp and paper production process. By eliminating sticking and buildup on rollers, these materials help to minimize web breaks and ensure a consistent, high-quality output. Moreover, their resistance to aggressive chemicals and high temperatures ensures that these roller surfaces can be easily cleaned and maintained without degrading the nonstick properties.

Section 3: Cost Savings and Efficiency Boost

The use of PTFE, PFA, and FEP heat shrinkable fluoropolymers in the pulp and paper industry leads to significant cost savings and efficiency boosts. By reducing sticking issues on rollers, these materials minimize downtime, lower maintenance costs, and enhance overall production efficiency. The long-lasting performance of these nonstick roller surfaces translates to a reduction in roller replacement expenses, providing a clear return on investment.

Section 4: The Future of Nonstick Rollers in Pulp and Paper

As the pulp and paper industry continues to evolve and demand for innovative solutions increases, heat shrinkable fluoropolymers like PTFE, PFA, and FEP are poised to play an even more significant role. Their unmatched nonstick properties, combined with their inherent chemical and thermal resistance, make these materials an essential component in the development of advanced, efficient, and cost-effective roller solutions.

Conclusion

PTFE, PFA, and FEP heat shrinkable fluoropolymers are transforming the pulp and paper industry with their unparalleled nonstick properties and cost-saving potential. By reducing sticking issues on rollers and enhancing production efficiency, these innovative materials are reshaping the landscape of cutting-edge engineering in the sector. As the industry continues to evolve, the potential for these fluoropolymers to contribute to new and groundbreaking applications is vast, further solidifying their importance in the development of advanced solutions in the pulp and paper industry.