It’s easy to overlook the seemingly mundane materials that hold the world together. But here’s the thing about hidden heroes – they quietly revolutionize industries. Fluoropolymers, a type of fluoroplastic, are exactly that for the oil and gas industry. Now, you may be asking, “What’s the big deal about these fluoropolymers?” Well, let’s dive into the world of oil and gas, where every component counts, and discover how these incredible materials are making a difference.

Fluoropolymers have been gaining traction in the oil and gas industry because of their remarkable properties, and for good reason. These unique materials can withstand the toughest environments – high pressure, extreme temperatures, and corrosive chemicals. In other words, they’re ready to endure everything the oil and gas industry can throw at them.

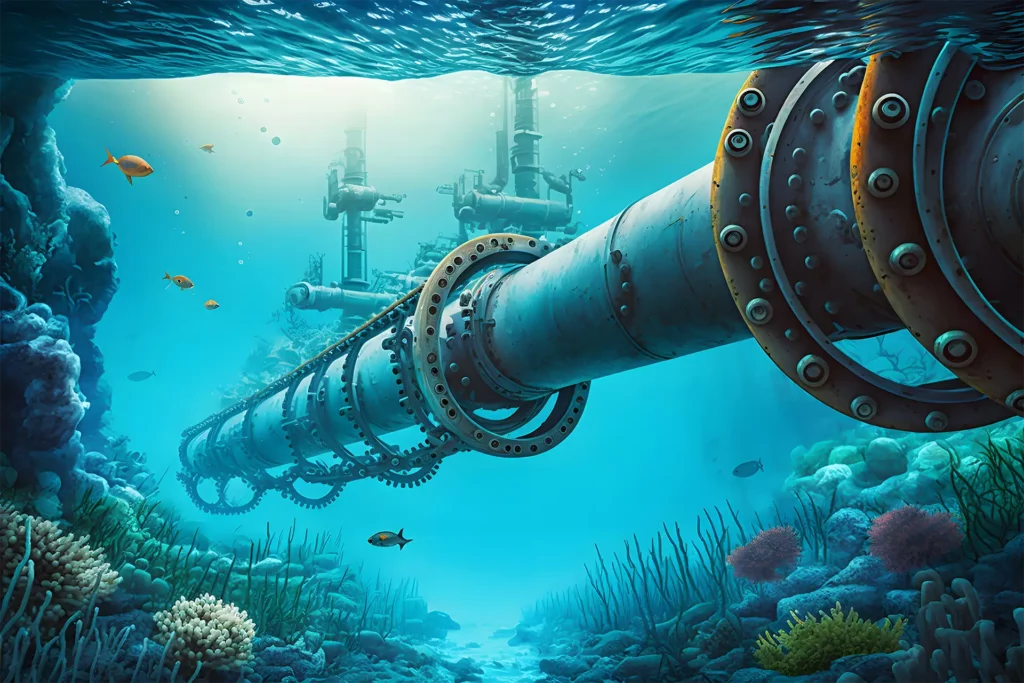

Think of the hazardous conditions down in oil wells. You’ve got high pressures, soaring temperatures, and a cocktail of corrosive chemicals. In this brutal environment, traditional materials struggle to keep up. That’s where fluoropolymers strut onto the scene. With their inherent toughness and resilience, they resist degradation and maintain their structural integrity, even in the face of such adversity.

But wait, there’s more. Ever heard of non-stick pans? Yes, the ones that make your morning pancakes a breeze. They’re coated with PTFE, a type of fluoropolymer. Now imagine applying that non-stick principle to the pipelines that transport oil and gas. Sounds good, doesn’t it? Reduced friction means less wear and tear on machinery and smoother flow of materials, making the entire process more efficient.

Fluoropolymers are also playing a crucial role in the area of seals and gaskets. In the high-stress world of oil and gas, leakage is a nightmare. The superior sealing capabilities of fluoropolymers like FFKM (perfluoroelastomer) have made them the go-to choice for critical sealing applications. They provide a reliable barrier against leaks, even under harsh conditions, significantly reducing the risk of catastrophic failures.

Let’s not forget about safety. Fire retardancy is another fantastic feature of fluoropolymers. When you’re dealing with oil and gas, flammability is always a concern. Fluoropolymers resist combustion, which means they can help prevent the spread of fire, a feature that cannot be overstated in this high-risk industry.

In summary, it’s clear that fluoropolymers have an essential role in the oil and gas industry. They’re helping drive efficiencies, reduce risks, and, let’s be honest, making life easier for the people working in these challenging environments. So, the next time you fill up your car, spare a thought for these mighty materials. They may be hidden, but they’re pivotal in bringing that precious fuel from deep underground to the pump at your local gas station.