Fluoron™: Industrial Nonstick Fluoropolymer Surface Solutions

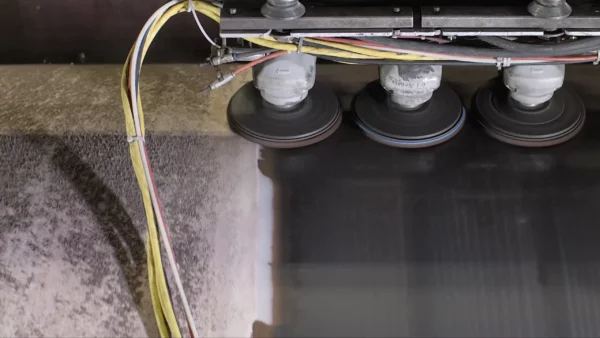

Teflon™ Sleeves and Covers

Fluoron’s non-stick sleeves offer protection from “stickies” and residue buildup while providing strong thermal and wear properties. Fluoron fabricates and installs custom FEP, PFA and PTFE sleeves to meet your requirements. Each sleeve is made from virgin Teflon® resin and produced to maximize fit, bonding and longevity.

Benefits:

- Eliminate process buildup and “stickies”

- glues, gums, starch, and scale

- Prevent corrosion

- Extend roller service life

- Reduce rubber roller repair

- Significantly reduces unplanned downtime

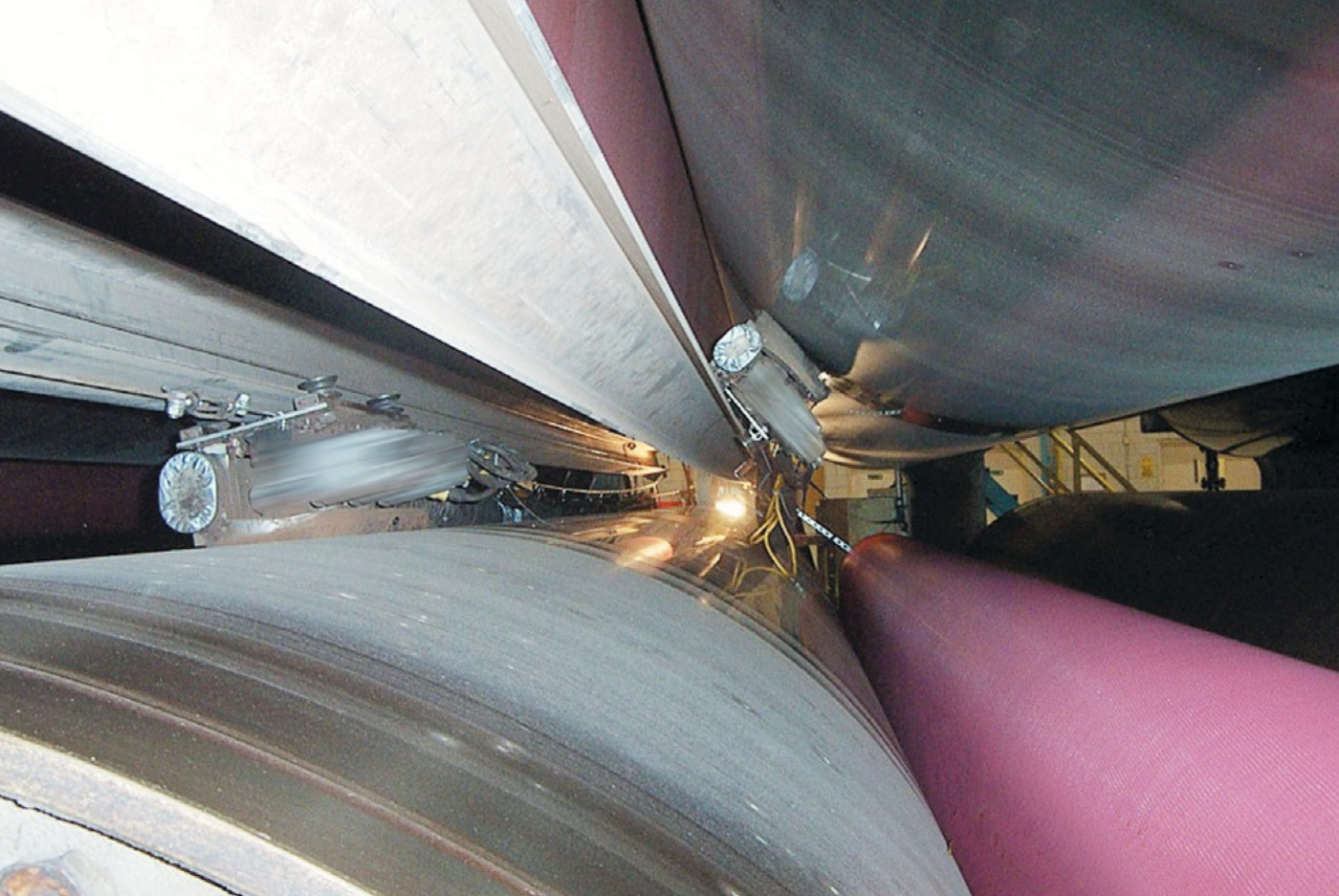

Dryer Can Covers

Fluoron’s innovative dryer covers are made from our FEP roll covers allowing for the best release from any build-up and residue. Our dryer can covers are accomplished with O.M.S. technology (On Machine Seaming) allowing for the cover to be installed without removing the dryer.

Benefits:

- Reduces the unwanted draw between dryers

- Heat transfer is not affected

- Improved product quality

- Less clean up time

- No doctoring

Our Mission:

Fastest Response Times

Committed To Problem Solving